News

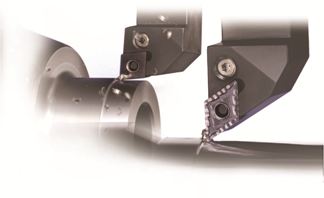

KYOCERA Introduces New MEGACOAT Cermet Cutting Tools in Grade PV7025 for General Machining of Steel

New products offer performance, cost advantages over carbide materials

MOUNTAIN HOME, N.C.-- Kyocera Industrial Ceramics Corporation, Cutting Tool Division today introduced its new PV7025 PVD-coated cermet grade of indexable cutting tool inserts for general machining of steel.

Featuring Kyocera's new proprietary MEGACOAT PVD* coating technology, PV7025 offers extraordinary wear resistance and heat resistance, providing superior durability in high-speed machining. When combined with a super micro-grain cermet substrate, the result is an exceptional cutting tool material for steel machining.

Kyocera's MEGACOAT Cermet features several key advantages, including:

- MEGACOAT Cermets are less chemically reactive than carbide, which reduces the tendency for built-up-edge and provides improved surface finishes.

- MEGACOAT Cermets are capable of running wet or dry, allowing reduced coolant costs and easier recycling of metal chips.

- Cermet pricing remains stable as compared to the rising cost of tungsten carbide.

- PV7025 maintains a Flexural Strength equivalent to P15 Carbide, making it capable of a wide range of cutting depths and feedrates, from continuous roughing to finishing applications.

PV7025 is the most recent addition to Kyocera's MEGACOAT Cermet family. Previously released grades include PV7010 for high-speed finishing of steel and PV7005 for cast iron machining. All three grades are currently available through a special sales promotion featuring introductory prices on popular geometries.

For additional information on these or other Kyocera Cutting Tool products, please contact:

Kyocera Industrial Ceramics Corporation

Cutting Tool Division

100 Industrial Park Road

Mountain Home, NC 28758

PH: 800-823-7284

email: ctsales@kyocera.com

website: kyocera.com/cuttingtools

*Physical Vapor Deposition (PVD) coating: A method whereby electrical or heat energy causes chemical reactions such as fusion and ionization to form a physical coating on the surface of the base material.

About Kyocera

Kyocera Industrial Ceramics Corporation (http://www.kyocera.com/kicc), headquartered in Mountain Home, NC, specializes in applying advanced materials and components to solve the most demanding engineering challenges. It is a wholly-owned subsidiary of Kyocera International, Inc. of San Diego, the North American holding company for Kyocera Corporation.

Kyocera Corporation (NYSE:KYO) (TOKYO:6971) (http://global.kyocera.com/), the parent and global headquarters of the Kyocera Group, was founded in 1959 as a producer of fine ceramics (also known as "advanced ceramics"). By combining these engineered materials with metals and plastics, and integrating them with other technologies, Kyocera has become a leading supplier of cutting tools, industrial components, electronic devices, semiconductor packages, solar power generating systems, office-document systems and telecommunications equipment. During the year ended March 31, 2011, the company's net sales totaled 1.27 trillion yen (approximately US$15.3 billion). Kyocera is ranked #604 on Forbes magazine's 2011 "Global 2000" listing of the world's largest publicly traded companies.

Contacts

Alarus Agency

619-235-4542

Stephanie Kellems

619-347-2715

skellems@alarus.biz

or

Leila Forsythe

619-708-4988

lforsythe@alarus.biz

Source: Kyocera Industrial Ceramics Corporation