News

KYOCERA Starts Mass Production of World's Fastest Inkjet Printheads for Commercial Printing

New printheads eject approximately 100 million drops/second (water-based ink) and 80 million drops/second (UV-curable ink)

Kyocera Corporation (President: Tetsuo Kuba) today announced that it will start mass production in April 2012 of two new inkjet printhead products "the KJ4B-Y for water-based ink and the KJ4A-B for UV-curable ink ”both offering the world's fastest print speeds1. New additions to Kyocera's KJ series, the printheads are key components for commercial inkjet printers. The company will initially produce 1,000 units per month (total for both types combined) and will gradually increase production volume.

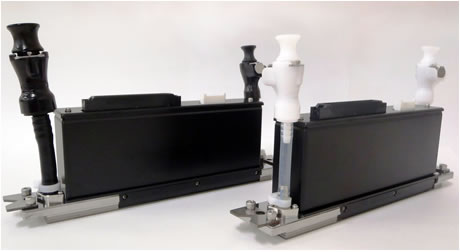

Kyocera inkjet printheads: KJ4A-B for UV-curable ink (left) and KJ4B-Y for water-based ink (right)

|

Model |

KJ4B-YH06WST-STDV (for water-based ink) KJ4A-BH06CST-STDC (for UV-curable ink) |

|

Production facility |

Kagoshima Kokubu Plant (Japan) |

|

Start of mass production |

April 2012 |

|

Production volume |

1,000 units per month (total for both types combined) |

|

Resolution |

600dpi |

|

Effective print width |

4.25 inches |

KJ4B-Y (for water-based ink)

This product provides high-resolution printing combined with a print speed that is approximately 1.3 times faster than Kyocera's conventional products, by ejecting ink up to 40,000 times per second (at 40kHz drive frequency) from each ink nozzle, resulting in approximately 100 million drops per second from a printhead with 2,656 nozzles. This allows for higher-speed and higher-resolution printing for large-volume print jobs with individualized data, such as invoices and statements, in a short period of time using water-based ink suitable for paper printing.

KJ4A-B (for UV-curable ink)

This product provides high-resolution printing combined with a print speed that is approximately 1.5 times faster than Kyocera's conventional products, by ejecting ink up to 30,000 times per second (at 30kHz drive frequency) from each ink nozzle, resulting in approximately 80 million drops per second from a printhead with 2,656 nozzles. This allows high-speed and high-resolution printing for an increasing number of commercial products, such as label printing for plastic and glass bottles and containers using UV-curable ink that enables printing on non-absorbent materials including films and plastics.

Kyocera has continuously provided the world's fastest inkjet printheads; each of these two new products has broken a new record. By introducing two new mass-produced products to the market, Kyocera strives to contribute to the higher-speed and higher-resolution printing required in the commercial printing industry.

Key Points in Commercialization

Kyocera leveraged its extensive knowledge of various printhead technologies as well as its wealth of design technologies to establish mass production techniques. Two key points include:

1. Mass-production technologies for piezo actuators through the application of piezo ceramic technologies cultivated by Kyocera.

2. Creating design technologies for ink flow channel structure and processing technologies for nozzle configurations.

Features

1. World's fastest high-resolution printing

Kyocera improved the piezo actuator for controlling the frequency and intensity of ink ejection and the programming to achieve high-frequency drive. In addition, enhancing the nozzle shape to improve drop placement accuracy enables the world's fastest high-resolution printing.

2. Design functionality

Both of the new products have a print width of 4.25 inches, thus requiring a fewer number of printheads for wide-format printing, which makes design work easier. It also allows for micron-level printhead alignment, as well as easy adjustment of ink tubing and wiring.

|

KJ4B-Y for water-based ink |

3. Applicable to various types of printing

The product lineup includes both water-based and UV-curable inks. This makes it possible to print not only on paper but also on a variety of other materials such as fabrics and plastic films. Because inkjet systems print without contacting the target material, this technology is expected to be used in a wider range of applications such as printing on textiles and printed electronics (e.g. printing and manufacturing of electronic circuits).

4. High reliability

Breaking the world's fastest print speed record, these new products also deliver the same drive durability performance as conventional products, where drive durability performance (ink ejection frequency) represents product durability. Furthermore, employing an externally sealed structure ensures the high reliability required for commercial printing.

Printing equipment manufacturers are aggressively developing new products in response to recent demands in commercial printing for smaller lot size, shorter delivery time, inventory reduction and variable printing2. Kyocera's KJ series high-speed and high-resolution printheads, including these new products, will contribute to the advancement of the printing industry.

*1 The world's fastest in single-pass inkjet printheads that print with a resolution of 600dpi x 600dpi, with a width of 4.25 inches, and one head for feed direction. Based on research by Kyocera (as of March 22, 2012).

*2 Variable printing: A printing method by which individually unique data (e.g., individual content of private ledger sheets, each of which is different from the other) is printed.