Kyocera to Showcase Customized 3D Printing, Cordierite and More at Ceramics Expo in Cleveland

Company’s additive manufacturing with virtually unlimited prototype designs, Cordierite for aerospace and Hi-Rel, plus other ceramics-based innovations will be on display at Kyocera Booth #726 Aug. 31-Sept. 1

- Corporate

- Industrial Ceramics

Cleveland, Ohio – August 31, 2021 – Kyocera has been advancing Fine Ceramics for 60 years in healthcare, communication, automotive, renewable energy and space exploration, among other industries. A world leader in advanced ceramics, Kyocera will showcase a new customized 3D printing service for cost-effective ceramic prototyping, Cordierite ceramic for aerospace and Hi-Rel applications, and many other ceramics-based innovations at booth #726 during the American Ceramic Society’s 2021 Ceramics Expo, August 31-September 1 — the world’s largest annual, admission-free exposition for the advanced ceramic and glass community.

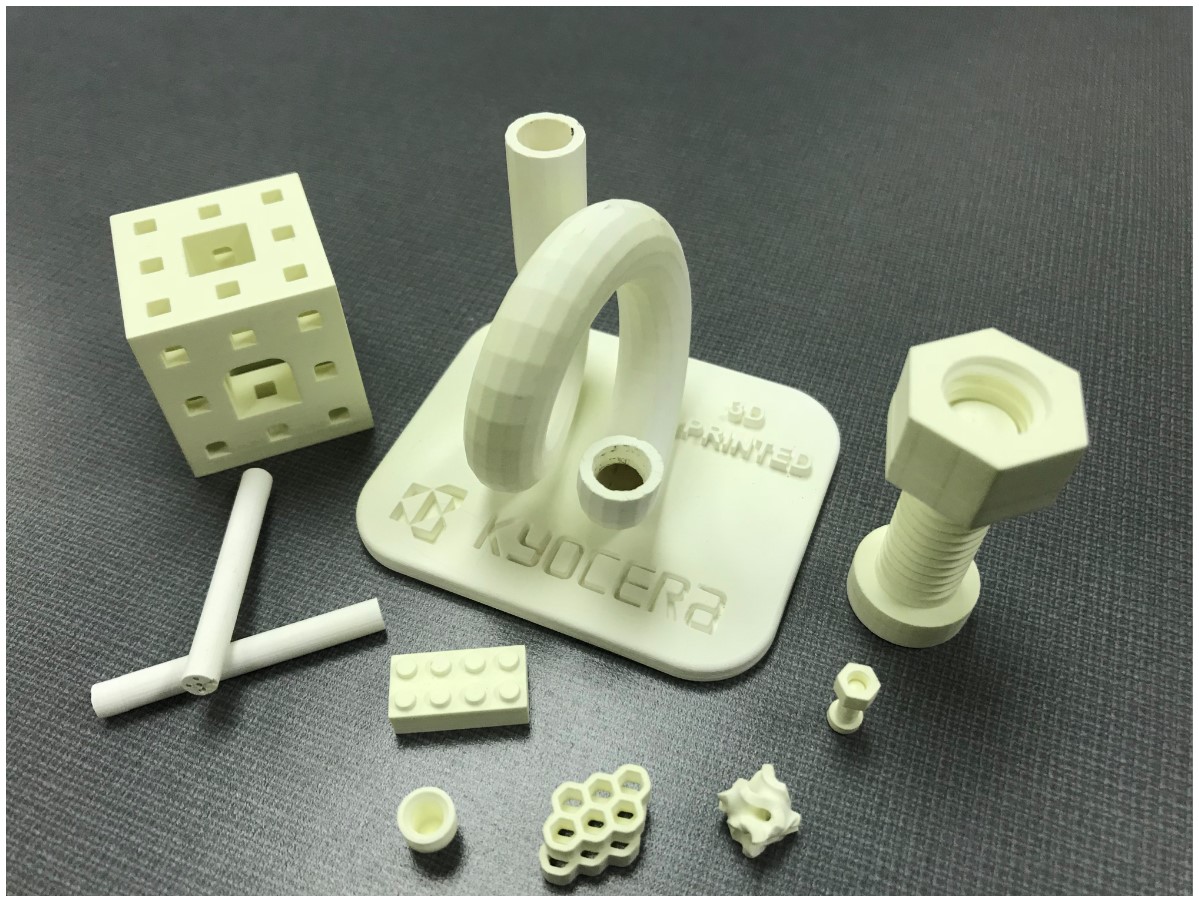

Kyocera’s new rapid, custom 3D printing service utilizes both zirconia and alumina materials in a wide variety of shapes and sizes. The simple 3-step process rapid-produces samples: simply send a 3D CAD file, complete a consultation the next day and then prototypes are quickly printed in 1-2 weeks*. Kyocera’s ceramics offer scratch resistance, higher rigidity, temperature resistance, longer lifetime, high-voltage insulation, lighter weight, and superior thermal management, providing an overall lower cost of ownership. 3D capabilities include:

- Shapes: Curved, Square, Angled, Sharp edges, Angled holes, Negative draft, Threads, Textures, Tiny holes

- Materials: Zirconia, Alumina

- Size: up to 200 x 105 x 40 mm

- Tolerance: +/-0.050 mm (as-fired)

- Wall Thickness: 0.25-10 mm

- Interlocking Assembly

- Smooth Surface

Cordierite Fine Ceramics and More Innovations

Kyocera’s latest innovations in Cordierite Fine Ceramics will also be highlighted at this year’s expo. Perfect for aerospace and Hi-Rel applications, Cordierite is found in the Subaru telescope in Hawaii where 18 individual Kyocera Cordierite components support a camera lens that looks at galaxies billions of light-years away. Lightweight, strong and highly versatile, Kyocera’s Cordierite is perfect for semiconductor equipment, optical components and robotic spacecraft, with these key features:

- Low coefficient of thermal expansion (CTE)

- Lightweight – approximately 70% weight reduction compared to conventional low-CTE glass+ via slim ribbed structure designed for high rigidity

- Highly versatile for complex parts

- Outstanding dimensional stability and rigidity

Additionally, Kyocera will showcase a number of other advanced ceramic innovations including:

- Highly specialized manufacturing for various industries: additive or machining; threaded holes, multiple holes

- Metallization technology, by which ceramics are “metallized” for soldering or brazing directly to metals

- Single-crystal sapphire, an ultra-hard, pure and transparent material used in applications ranging from highly scratch-resistant windows to LED substrates

- Heat-resistant ceramics used in foundries, gas turbines and automotive engines

- Chemical-resistant ceramics for pump, valve and seal components exposed to corrosive fluids

- Gas nozzles for high-temperature furnace applications, supporting rings for semiconductor processing equipment, and sealing ring samples

- High purity Alumina (A480S) crucibles

- Mud pump liners

- Plastic injection over molding for textile components

“Today’s ceramics are a key material fueling innovations in electronics, IoT, automotive, aerospace and medical technologies, to name a few,” said Mr. Mark Wolf, Kyocera International, Inc.’s V.P. of Fine Ceramics Group. “Although lightweight, Kyocera’s ceramics are among the strongest and hardest known materials. They conduct heat, but not electricity; they resist abrasion and are impervious to corrosion; they can be machined to extremely precise dimensions and still withstand temperatures that would melt most metals. And now, we’re able to create rapid prototypes to help speed up the design and manufacturing process for tomorrow’s innovations.”

Wolf will moderate a panel discussion, “Reimagining the Supply Chain: Lessons for Efficiency in the Wake of the COVID-19 Pandemic,” at 9:30am, August 31, at the Expo.

Kyocera offers ceramic materials in approximately 200 different formulations, including Aluminum Oxide, Aluminum Nitride, Cermet, Cordierite, Forsterite, Mullite, Sapphire, Silicon Carbide, Silicon Nitride, Steatite, Yttria, Zirconia, and others. The company has developed a wide range of proprietary process technologies that can incorporate dry-pressing, cold-isostatic pressing, hot-isostatic pressing, injection molding, tape casting, multilayering and/or metallizing ceramics.

Click to learn more about Kyocera’s Fine Ceramics solutions. To schedule a dedicated booth appointment or for more information on customized 3D printing, please email FCsales@kyocera.com.

*Rapid production in 7-14 days if hard grinding or polishing is not required. Each project production timeline will be estimated based on consultation.

+Based on Kyocera research

Kyocera Corporation (TOKYO: 6971), the parent and global headquarters of the Kyocera Group, was founded in 1959 as a producer of fine ceramics (also known as “advanced ceramics”). By combining these engineered materials with metals and integrating them with other technologies, Kyocera has become a leading supplier of industrial and automotive components, semiconductor packages, electronic devices, smart energy systems, printers, copiers, and mobile phones. During the year ended March 31, 2021, the company’s consolidated sales revenue totaled 1.5 trillion yen (approx. US$13.8 billion). Kyocera is ranked #603 on Forbes magazine’s 2021 “Global 2000” list of the world’s largest publicly traded companies, and appears on The Wall Street Journal’s latest list of “The World’s 100 Most Sustainably Managed Companies.”

-

Media Contact

leasa@lpicommunications.com

Leasa Ireland, LPI Communications for Kyocera, 310.750.7082