- Packaging

- By Application

- By Material

- By Type

- Antenna

- BGA

- Ceramic Package Lids

- Communication Modules

- Ceramic Quad Flat Pack (CQFP)

- Eyelet Power Packages

- Flip Chip Packaging and Assembly

- GaN & SiC Packages

- Hermetic

- LCC

- LDMOS

- MCM

- MMIC Packages

- Optoelectronic Components

- Organic Semiconductor Packages

- Power Transistor Packages

- Transmit / Receive Modules

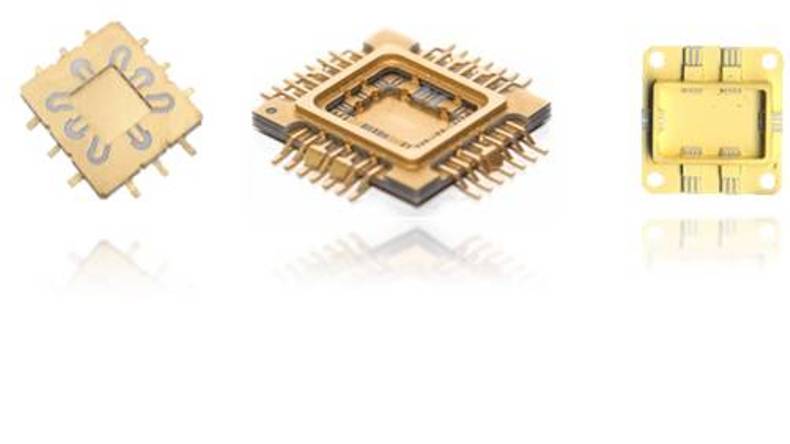

MMIC Packages & Modules

As the operating frequency of a die increases, the package parasitics become an ever increasing challenge to system performance. To minimize these effects, the package materials, layout, and characteristic impedance must be designed to minimize return loss and unwanted resonances. Applications for MMIC packages primarily include hi-rel, aerospace, telecommunications, and medical.

Kyocera International has many years of experience in designing custom MMIC packages for GaAs, Si, and GaN devices. To ensure the manufacturability of the design, Kyocera International's electrical engineers utilize the best modeling and simulation software to optimize the package electrical performance.

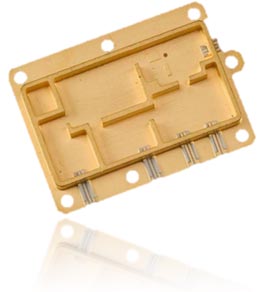

Thermal management in your high frequency application is becoming increasingly important to overall system performance. Kyocera International's MMIC packages and modules include flange materials such as ASTM F-15, W/Cu, Mo/Cu or Cu/Mo/Cu, or other composites for higher thermal conductivity.

High temperature Ag/Cu and Ag/Cu/In braze is typically used to attach flanges and connectors for maximum thermal conduction and mechanical integrity. Au/Ge and Au/Sn braze materials can be used when lower temperature brazing is needed.

Open-tooled parts and feedthroughs are also available for shorter lead times.